purpose of impact strength test|izod impact notched vs unnotched : solutions In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a . WEB1 dia atrás · OS MAIORES VILÕES DAS ACOMPANHANTES. OS MAIORES VILÕES DAS ACOMPANHANTES - Sabe aquele espaço que faltava para vcs se defenderem, pois .

{plog:ftitle_list}

webWelcome!!! * I recommend use PC to subscribe. ** Boosty App mobile dont have private chat to sent messages, please check your account on PC. -- Hi, I'm Daval, I'm creating Taboo .

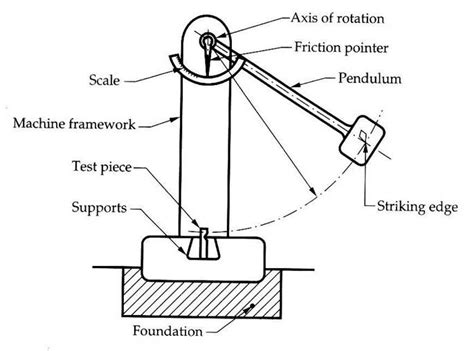

Impact testing is a critical evaluation process that determines a material or product’s toughness, resilience, and durability when subjected to sudden forces or . Impact testing is a procedure that measures a material’s resistance to failure when subjected to high-rate loading. This method is used in multiple industries like automotive, aerospace, and construction to .The Izod impact strength test is an ASTM standard method of determining the impact resistance of materials. A pivoting arm is raised to a specific height (constant potential energy) and then released. The arm swings down hitting a notched sample, breaking the specimen. The energy absorbed by the sample is calculated from the height the arm swings to after hitting the sample. A notche.

In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a .

The scope of these impact test is to measure the answer of a standard test specimen to the pendulum-type impact load. The result is expressed in term of kinetic energy consumed by . The Charpy impact test, sometimes called a V-notch test, is a comparative-style test used to define a material’s impact strength by determining how much energy is required to fracture a pre-prepared and .The objective of the Charpy impact test to ISO 148-1 is the determination of the impact energy and determination of the impact strength of a metal. The test indicates whether the metal is tough or brittle. In addition, the tough/brittle .

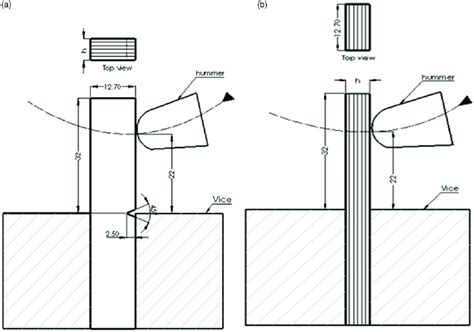

The purpose of impact testing is to measure an object's ability to resist high-rate loading. It is usually thought of in terms of two objects striking each other at high relative speeds. A part, or material's ability to resist impact . IZOD test is vertical while Charpy tests are horizontal but both measure impact resistance. The main difference lies within a notch sample orientation during testing where in an Izod notched bar impact test, the specimen stands vertically with its notch facing towards the pendulum whereas, during charpy v-notch impact test ,the samples are placed horizontally .Tensile impact test procedures. The tensile impact strength test was originally developed to overcome the deficiencies of flexural (both Izod and Charpy) impact test. All the test variables that have a high effect on the results, such as notch sensitivity, toss factor and specimen thickness, are eliminated in the tensile impact test. The purpose of both Charpy and IZOD tests when correctly performed is the parting or fracture of the material sample, into two or more pieces. . What Are the Applications of Impact Strength? While impact strength testing cannot provide an absolute reference point in the design of components, it is a necessary scaling measurement. .

The unit of impact strength is J/m2. Repeat Test: If it is desired to determine the ductile-to-brittle transition temperature, the tests can be repeated at multiple temperatures to plot the impact energy vs. temperature. Prepare Report: Finally, a report can be prepared to note the test procedure, the standard used, and the test results. The .

izod impact test diagram

How Charpy impact tests are performed. Specimen Preparation: A small, standardized specimen, usually a rectangular bar with a V-shaped notch machined on one side.The notch creates a stress concentration that promotes fracture when impacted. The test setup includes a pendulum hammer, a notched specimen holder, and a digital or analog .Test Properties Yield Strength. The yield strength is the point at which plastic deformation occurs under stress. This is determined during testing over a measured gauge length via the use of devices known as extensometers. The devices may be either be mechanical clip on or video where non-contact is a limitation, e.g. elevated temperature testing.

gas spring testing machine impact tester

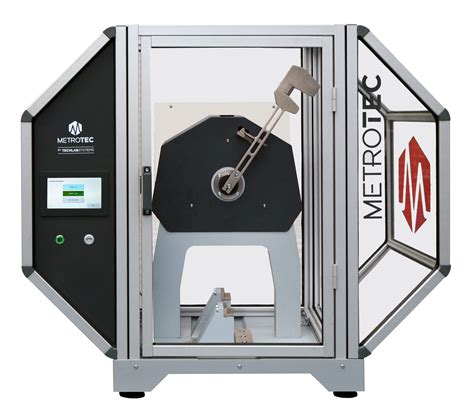

Tensile testing is a destructive test process that provides information about the tensile strength, yield strength, and ductility of the metallic material. It measures the force required to break a composite or plastic specimen and the extent to which .ZwickRoell impact strength testing machines: the right pendulum impact testers and drop weight testers for your applications. Impact testing has become firmly established in materials and components testing. The properties determined are part of basic material characterization. ZwickRoell has been delivering quality impact test equipment for years.The testing procedure can also impact the compressive strength test results. Any deviations from the standard procedures can lead to variations in the results. It is important to ensure that the testing apparatus is calibrated and maintained properly to obtain reliable results. Compressive Strength Test of Concrete

The Charpy impact test, also known as the Charpy V-notch test, is a high strain-rate test that involves striking a standard notched specimen with a controlled weight pendulum swung from a set height. The impact test helps measure the amount .Tensile impact test procedures. The tensile impact strength test was originally developed to overcome the deficiencies of flexural (both Izod and Charpy) impact test. All the test variables that have a high effect on the results, such as notch sensitivity, toss factor and specimen thickness, are eliminated in the tensile impact test.An overview of mechanical and physical testing of composite materials. N. Saba, . M.T.H. Sultan, in Mechanical and Physical Testing of Biocomposites, Fibre-Reinforced Composites and Hybrid Composites, 2019 1.2.3 Impact test. The impact test is designed to determine how a specimen of a known material such as polymers, ceramics, and composites will respond to a .

izod impact strength chart

The impact test is a method for evaluating the toughness, impact strength and notch sensitivity of engineering materials. Engineers test the ability of a material to withstand impact to predict its behavior under actual conditions. Many materials fail suddenly under impact, at flaws/cracks or notches. The most common impact tests use a swinging . Another purpose of Weld Testing is to ensure that the welds meet the requirements for mechanical and technological properties for their intended use. . Destructive testing is used to evaluate the strength, soundness and .

If impact testing is carried out over a range of temperatures the results of energy absorbed versus temperature can be plotted to give the 'S' curve illustrated in Fig.3. . The next article in this series will look at the testing of welds, how the .Charpy Impact Testing is essentially a stress test for materials. While lifting weights helps us gauge our physical strength, this testing method serves as an indicator of the ability of metals and other materials to withstand sudden impact or shock. Imagine you have two different types of metal, one for building bridges and another for making .

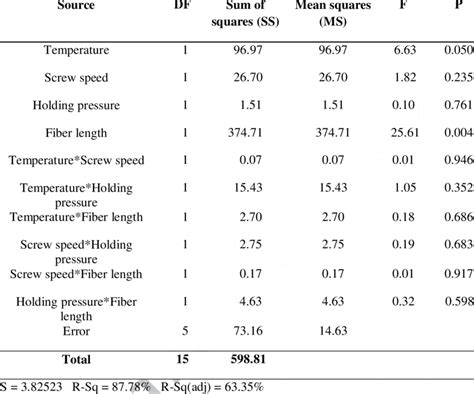

The test result is typically the average of 5 specimens. ISO impact strength is expressed in kJ/m2. Impact strength is calculated by dividing impact energy in J by the area under the notch. The test result is typically the average of 10 specimens. The higher the resulting numbers the tougher the material.

Impact testing is a type of mechanical testing used to determine how a material responds to high strain-rate loading. It involves instrumented equipment measuring loads and energy absorbed by the material when it fractur es. The results help to determine the notch toughness of the material and its suitability for a given application.The impact test is the ability of a material to absorb energy during plastic deformation. It signifies toughness or impact strength of a material. This energy absorption is related to the brittleness of the material. . performances, characteristics and cost are given for information purpose only. Although the data and information contained in .

In this guide, we will delve into the essence of the Charpy impact test, exploring the purpose, procedure, applications, and significance of diverse materials. Understanding the Charpy Impact Test: A Primer . The Charpy impact test is vital for evaluating a material’s strength under dynamic conditions. It offers a practical understanding of . ASTM D256 outlines the Izod impact test for plastics, emphasizing specimen preparation and machine calibration for accurate impact resistance data. . The purpose of the notch is to serve as a stress concentrator. The notch is probably the most critical part of specimen preparation and there is tight tolerance defined by ASTM D256 on the depth .

Because the pendulum hits the unnotched side of the sample in the Charpy test, Charpy values have significantly higher impact strength than the Izod test. As shown in Fig. 7.14, the Izod impact tester consists of a similar setup as in a Charpy tester. Based on the same principle, a slight difference is in the effective length of the pendulum. .

izod impact notched vs unnotched

An assessment of muscle strength is typically performed as part of a patient's objective assessment and is an important component of the physical exam that can reveal information about neurologic deficits. It is used to evaluate weakness and can be effective in differentiating true weakness from imbalance or poor endurance. It may be referred to as motor testing, . Testing of Impact Strength When metal is subjected to suddenly applied load or stress, it may fail. . The impact test measures the energy necessary to fracture a standard notched bar by an impulse load and as such is an indication of the notch toughness of the material under shock loading. Izod test and the Charpy test are commonly performed .

Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, stiffness, density) or to the material behavior under certain stresses (e.g., abrasion .

air spring leak testing machine

air spring test machine

Resultado da No ZAP Imóveis você encontra Imóveis para alugar em Guaxindiba, São Gonçalo, RJ. Confira as melhores ofertas de imóveis para alugar e feche .

purpose of impact strength test|izod impact notched vs unnotched